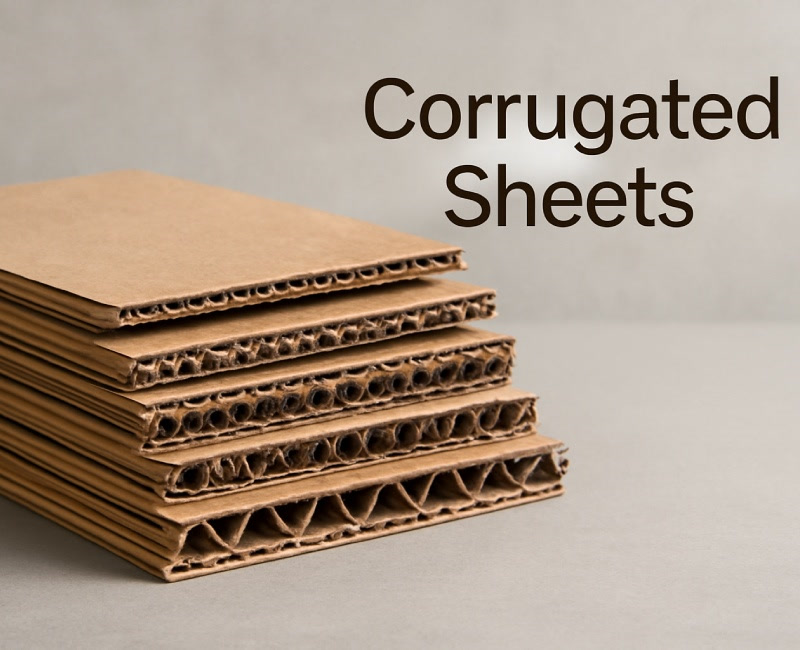

At Rudra Pack Industries (Shiv Multi Pack), corrugated sheets are engineered for strength, consistency, and versatility—ideal for protective layering, dividers, stacking stability, and custom die-cut components across many industries. Corrugated paperboard performance depends on flute profile and GSM selection, which we tailor based on load, cushioning, and print needs.

What Are Corrugated Sheets?

Corrugated sheets are flat panels of corrugated board used as protective layers, dividers, pads, and custom components inside packaging, improving stability and preventing product-to-product contact during transport and storage. They are valued for strength, durability, and flexibility while remaining lightweight and cost-effective for large-scale logistics.

Technical Options We Offer

Benefits

Use-Cases

3-Column Sub-Products Grid

| Sr. No. | Product | Features |

|---|---|---|

| 1 | Corrugated Layer Pads |

Flat sheets used between product layers for anti-abrasion and load distribution. Improve stack stability and reduce transit damage in cartons and on pallets. |

| 2 | Corrugated Dividers |

Slotted or die-cut partitions that separate items inside a box. Prevents product-to-product contact and enhances packing efficiency. |

| 3 | Corrugated Pads & Liners |

Base/top pads and carton liners to reinforce boxes and protect surfaces. Useful for fragile, coated, or polished items needing scratch protection. |

| 4 | Custom Die-Cut Sheets |

Precision-cut sheets for inserts, braces, vents, or product-shaped supports. Optimized flute/GSM for cushioning, fit, and assembly speed. |

| 5 | Print-Ready Corrugated Sheets (E/F Flute) |

Fine-flute sheets with smooth surfaces for high-quality branding and instructions. Ideal for retail packs, inner cards, and lightweight product supports. |

| 6 | Heavy-Duty Double-Wall Sheets (BC/EB) |

Rigid boards for high stacking strength and tough transit conditions. Suited to industrial, automotive, and export packaging lines. |

Applications of Corrugated Sheets

How We Specify the Right Sheet